When combustion engines are running, uneven torque is generated on the shaft. Even with progressive configurations such as V6, V8 and V12, the speed of the crankshaft is not stable. Added to all this are jumps from the timing and auxiliary units in the power plant.

To eliminate the negative impact and minimize fluctuations, car manufacturers have developed a special mechanism - a dual-mass flywheel. We suggest that you familiarize yourself with the structural features of such a part and troubleshooting methods.

General information

According to statistics, about 75% of new vehicles are produced with a dual-mass flywheel (abbreviated as DMF). This part was previously used preferably in models with diesel power units, but today it has begun to appear on cars with gasoline engines. The DMF is combined with dual clutch transmissions and separate variable transmission outlets.

The first mentions of the installation of flywheels appeared in the mid-80s. last century, and they received mass distribution only in the late 90s.

Several decades ago, drivers did not even realize that such vibration dampers were present in their cars, because due to the low power of the motors, they served as long and uninterruptedly as possible. But with the increase in productivity and the emergence of stringent requirements for harmful emissions of the exhaust system, the DMF turned into a mechanism vulnerable to wear with a working resource of 150-250 thousand km.

In most cases, replacing a clutch in a car is accompanied by the purchase of a new dual-mass flywheel. In the process of dismantling the assembly, experts determine that it is badly worn out and can no longer be operated with a new clutch kit. And since the installation of a new DMF requires dismantling of the entire system, it is advisable to install it together with the clutch.

Purpose and function of the dual-mass flywheel

The DMF is a complete rotational vibration damper that is an alternative to the damping spring set found in the clutch disc.

Previously, cars used single-mass flywheels, which are a cast disc without moving elements. Such parts were less exposed to wear, but as the power of the engines grew, they ceased to cope with their tasks and were replaced by a more progressive solution.

The dual-mass flywheel consists of the following parts:

- main building;

- auxiliary building;

- package of soft springs;

- package of rigid springs;

- planetary gear;

- radial bearing;

- axial bearing;

- wheel with internal teeth;

- corkscrew pin hole;

- hole cover for pumping grease;

- separating slider for spring packages.

The mechanism is designed to smooth out the transmission during aggressive operation. In cars with a classic single-mass flywheel, acceleration in high gear is accompanied by significant vibrations, and subsequent acceleration without engaging a lower gear becomes impossible.

In modern vehicles with DMF, these manifestations are practically absent, although the engine enters into "resonance". This is due to the presence of powerful springs that suppress much of the vibration and noise.

How to check a dual-mass flywheel

In the event of extraneous sounds and vibrations during engine operation, even in idle mode, attention should be paid to the condition of the dual-mass flywheel. However, such symptoms may indicate other problems - for example, failure of the injection pump, clamping of the supports and breakdown of the starting mechanism.

Timely and thorough diagnostics of the part will allow you to determine the degree of performance and make repairs on time.

If the flywheel is cracked due to high temperatures, the disc will need to be replaced. Also, this procedure is necessary when the lubricant is quickly consumed from the clutch housing. Any smudges on the plane of the part and nearby mechanisms are unacceptable.

An important sign of breakdowns can be a jam, as a result of which it is not possible to turn the disc in any direction. The malfunction appears when the structure and fasteners are deformed.

But a visual inspection of the mechanism does not allow making a conclusion about its condition. To get more information, you need to completely check the flywheel or go to a car repair shop for diagnostics.

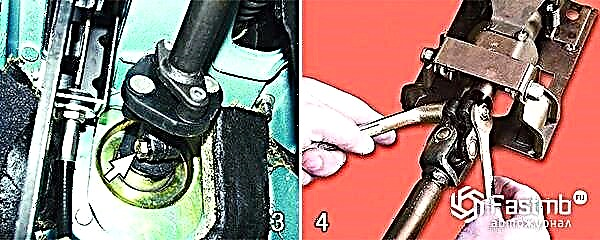

When self-assessment, you need to look at the angle of displacement of the flywheel in two directions. You can do it with your hands or with a pry bar. The key requirement is to direct the disc to one of its working positions.

It is important to note that in diesel engines it is quite difficult to displace the disc. This is due to the presence of a friction ring. To turn the flywheel in a diesel engine, you need to use a crank mechanism.

In the presence of resistance from the flywheel, even minimal resistance, one can conclude that it is functioning properly. If you do not need to exert much effort to spin the disk, this indicates some kind of failure.

Flywheel problems may be indicated by partial seizure of the disc or problems with the rotation of the part. Loud noise is a sign of insufficient lubrication or damaged dampers.

At the next stage of self-diagnosis, you will need to check the effectiveness of the movement function. If in the first case the angle of displacement in two directions is estimated, now it is backlash.

Reconstruction of two-mass flywheels

If there are all signs that the flywheel is out of order, then the only way out is to replace the part. But in the absence of finances and a desire to buy a new unit, work can be carried out to restore operability. In this case, the costs will be reduced to 10 thousand rubles.

It is important to keep in mind that experts and car owners speak differently about the regeneration of dual-mass flywheels. Leading manufacturers of such units do not provide for the possibility of restoration, therefore it is problematic to find spare parts on the free sale.

To avoid expensive replacement or repair of the flywheel, it is recommended to check it once or twice a year. The exact terms are determined taking into account the intensity of vehicle operation and the characteristics of the vehicle.

If, when using a machine with a dual-mass flywheel, significant vibration or rattling is detected, especially at idle speed, contact the service center for assistance as soon as possible. Most likely, the problems are caused by a broken DMF. If you continue to operate a car with such a breakdown, the flywheel will become unusable.

In addition, the service life of the mechanism depends on the driving style. Experts identify several types of riding:

- Economy mode with frequent gear changes poses a threat to the flywheel. Acceleration from low gears has a particularly negative effect on the condition of the part.

- Sporty manner. A sharp afterburner is accompanied by significant jerks, contributing to the overload of the spring system.

- Frequent towing, carrying heavy loads, etc. This driving style is dangerous not only for the damping mechanism, but also for the transmission.

- City exploitation. Becoming a big challenge for a 2-mass flywheel.

Frequent starts and accelerations negatively affect the operational resource of the mechanism.

Among the additional negative factors causing rapid flywheel wear, chip tuning is distinguished. The part is designed taking into account the expected loads, therefore, a deviation from the permissible standards provokes its damage.

Another reason for vibrations and damage to the flywheel is the technical condition of the vehicle. So, if the engine does not function correctly, for example, due to improper functioning of the injection system, the vibrations become as strong as possible. Long-term operation with a failed motor reduces the operational life of the DMF.

Popular dual-mass flywheel malfunctions

Exist some of the most common flywheel problems... Among them:

- Gear wear. The presence of chips or abrasion of several teeth can be understood by the characteristic knocking when starting the starter. The problem is corrected by installing a new part.

- Beating. If vibration vibrations are present at low revs, most likely damage to the clutch mechanism has occurred, or the disc was installed incorrectly during scheduled repairs. The defect can be eliminated by centering the part together with the clutch. If not wear caused the malfunctions, you will need to replace the unit.

- Damage to the adjacent surface. Seizures appear due to malfunctioning of the clutch mechanism. If wear is not critical, vibration, noise, and puffing caused by the driven disc can be eliminated by adjusting the part. In other cases, replacement will be required.

- Defects on the adjoining surface under the crankshaft. With diligent and intensive use of the vehicle, such errors are inevitable.

The situation with partial wear of the DMF is dangerous because the car continues to drive, but its operation is accompanied by noise, vibrations and other errors. Over time, the resource of components comes to an end, which provokes either a minor breakdown in the transmission system, or engine failure. In addition, the problem results in limited power transmission and lack of traction.

Experienced car owners are able to identify faults with dual-mass flywheels on their own. Among them: loss of lubrication, knocking at idle or with a cold engine, strange sounding of the power plant in neutral gear, vibration, etc.

You can replace the part yourself by following a few preparatory steps:

- remove the propeller shaft;

- turn off the starter by de-energizing it by dismantling the electrical wiring from the relay;

- if necessary, remove the gearbox;

- dismantle the clutch;

- remove the flywheel with a driven disk.

Replacing a dual-mass flywheel with your own hands is easy. The main thing is to get basic theoretical data, prepare tools and consumables. In the absence of experience, it is better to immediately seek help from a specialized service center. Experts will conduct global diagnostics and troubleshooting, eliminating all errors. This will be followed by grinding, cleaning and lubricating the flywheel.

Dual mass flywheel price

After the introduction of dual-mass flywheels on the market, the cost of clutch repair services became equal to the restoration of an automatic transmission. It is almost impossible to repair the flywheel, so you have to buy a new part and install it in place of the failed mechanism.

The average price of a new two-mass flywheel is 15 thousand rubles, but it can reach 50 thousand rubles. depending on the characteristics of the vehicle.

Leading car manufacturers offer ready-made kits that include a clutch mechanism and a basket with a classic single-mass flywheel. The choice of such components allows you to save up to 20-30%.

Conclusion

Many car owners treat dual-mass flywheels as an unnecessary and bad part, trying to remove it as soon as possible. But after installing a kit with a simple flywheel, they understand how much the DMF improves the comfort of the vehicle. Therefore, experts recommend taking a responsible approach to the care of the mechanism and promptly eliminating any malfunctions that have arisen.

|| list |

- general information

- Purpose and function of the dual-mass flywheel

- How to check a dual-mass flywheel

- Reconstruction of two-mass flywheels

- Popular dual-mass flywheel malfunctions

- Dual mass flywheel price